Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

Wuhan we-all iron and steel co.,Ltd

|

Textile Humidification Machine

|

|

|

|

|

Main steel grade Carries out the standard

A,B,D,E(Z15.Z25.Z35)

AH32-FH32(Z15.Z25.Z35)

AH36-FH36(Z15.Z25.Z35)

API SPEC 2H Gr.42.Gr.50 A131(GrA,B,D,E,CS,AH32,AH36,DH32,DH36,EH32,EH36, FH32,FH36,AH40,DH40,EH40,FH40 2H(Gr42,50) 2W(TMCP)(Gr42,50,50T)

A32,A36,A40,D32,D36,D40,E32,E36,E40,F32,F36,F40 A420,A460,A500,A550,A620,A690,D420,D460,D500,D550,D620,D690 E420,E460,E500,E550,E620,E690,F420,F460,F500,F550,F620,F690 A27S,D27S,E27S , NV360-0A,-0N,NV360-1FN NV410-0A,-0N,NV410-1FN,NV460-0A,-0N,NV460-1FN NV490-0N,NV490-1FN,NV510-1FN NV0.3Mo,NV1Cr0.5Mo,NV2.25Cr1Mo 360,410,460,490,360FG,410FG,460FG,490FG,510FG 13CrMn4-5,11CrMo9-10 AH42,AH46,AH50,AH55,AH62,AH69,DH42,DH46,DH50,DH55,DH62,DH69 EH42,EH46,EH50,EH55,EH55,EH62,EH69,FH42,FH46,FH50,FH55,FH62 FH69,1.5Ni,3.5Ni,5Ni,9Ni,B420,B460,B500,N15,N35,N50,N90 M,CIM,C2M1,KA32,KA36,KA40,KF32,D32,D36,D40,F36,E32,E36,E40,F40 KP42,KP46,KP49,KPA46,KPA49,KPV24,KPV32,KPV36,KPV46,KPV50 CCS,DNV,GL,

LR,BV,ABS,

GB5313

API

Main use Uses in manufacturing the hull, the marine extraction platform, the platform tube contact and other structural elements.

|

|

|

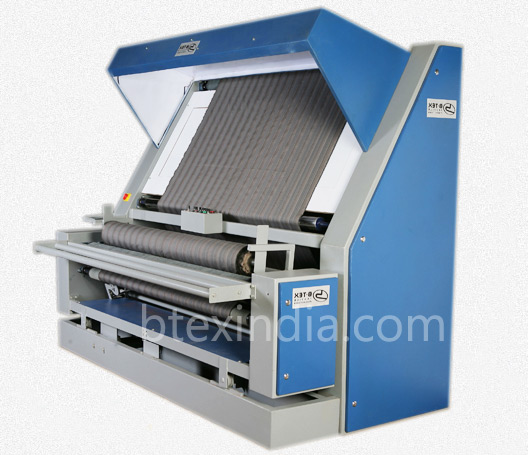

B-Tex Textile Machinery

|

Textile Humidification Machine

|

|

|

|

|

Nirvana means peace, as the name suggests this machine will surely deliver peace of mind and quality. Nirvana is designed on guidelines of one of the Italian design of inspection system and is only supplied for inspection of finish fabric. Fully P.L.C. controls allows to synchronies the fabric at every point of flow to ensure zero stretch or elongation. Six positive driven rollers smoothly carries the fabric from start to end and delivers crease-free, compact, edge aligned presentable rolls. Nirvana delivers the same quality of fabric, which you had made with dedication and efforts but without defects.

Features

Fabric inlet from roll, flat fold or big batch rolls (Axial or Arm Type)

Fabric outlet from roll form

6 Positive Driven Rolls

Laminated inspection table with opaque glass

Fabric edge guider for straight edged fabric rolls

Fully P.L.C. Panel

Double Dancing roller Mechanism

A. C. Inverter Drives

Imported Emery

Electronic length counter meter

Anti-Crease Rollers

Adjustable roll hardness

Variable illumination inside and over the table

Wooden platform

Variable speed from 0 to 70 mtrs/min

Full length reversing and Inching

Powder coated external touch

|

|

|

B-Tex Textile Machinery

|

Textile Humidification Machine

|

|

|

|

|

B-Tex Inspection Machine, BIM-IRR is a perfect and reliable tool for detecting fabric defects and incorrect sizes for delicate fabrics in Roll to Roll Form. Specially made for Silk, Knits and Lycra types of Fabrics, where fabric tension is controlled by PLC Multi-Drive Synchronisation Technology. It is proved against lab test that BIM-IRR delivers creaseless fabric roll without stretch and elongation. In BIM-IRR, fabric rolling is done in front of the operator and so the machine take very less working space.

Features

Fabric inlet from roll or flat fold Form

Fabric outlet in roll form (Rolling In-front of the operator)

Adjustable Fabric Tension

Auto-Stop at feed, if machine running out of fabric

Laminated Inspection Table

Top & Bottom Lights

Length Counter Meter for fabric length measurement

Sensor type Edge Guiding for presentable roll (No Air or Oil required)

Full Length reversing for rechecking with Jog/Inching operation

S.S. Scroll Roller for creaseless fabric roll

Dancing Roller Mechanism for Multi Drive Synchronisation

Guide Rollers with Smooth finish

A.C. Inverter Drive with In-built software (Low electricity consumption)

Imported rubber emery on winding roll for extra life

Variable speed from 0 - 60 meter/min.

Italian geared-motors on all positive driven rolls

Utility Tray and Single phase Switch box is provided

Safety sensors and Emergency stop is provided

|

|

|

B-Tex Textile Machinery

|

Textile Humidification Machine

|

|

|

|

|

-Tex Inspection Machine, BIM-BRR is a perfect and reliable tool for detecting fabric defects and incorrect sizes for all types of Fabric in Roll to Roll Form. BIM-RR guarantees that only high quality fabric is delivered at economic cost. It can be used for grey, Semi-Finish and finish fabric inspection. Also BIM-BRR can be equipped with PLC and Data Logging Systems for inspection report generation.

Features

Fabric inlet from roll or flat fold Form

Fabric outlet in roll form

Adjustable Fabric Tension

Auto-Stop at feed, if machine running out of fabric

Laminated Inspection Table

Top & Bottom Lights

Length Counter Meter for fabric length measurement

Sensor type Edge Guiding for presentable roll (No Air or Oil required)

Full Length reversing for rechecking with Jog/Inching operation

S.S. Scroll Roller for creaseless fabric roll

Adjustable roll Compactness

Dancing Roller Mechanism for Multi Drive Synchronisation

Guide Rollers with Smooth finish

Wooden Platform for Operator

A.C. Inverter Drive with In-built software (Low electricity consumption)

Imported rubber emery on winding roll for extra life

Variable speed from 0 - 60 meter/min.

Italian geared-motors on all positive driven rolls

Utility Tray and Single phase Switch box is provided

Safety sensors and Emergency stop is provided

|

|

|

B-Tex Textile Machinery

|

Textile Humidification Machine

|

|

|

|

|

B-Tex Inspection Machine, BIM – BB+RR is a perfect and reliable tool for detecting fabric defects and incorrect sizes for all types of Fabric Batch to Roll From.

It can be used for grey, Semi-Finish and finish fabric inspection, Where fabric is feed through a Big-Batch Trolley and delivered in Roll Form. Batch Arm is provided with pneumatic cylinder for Uniform Surface Un-winding of Big-Batch. If required fabric can also be feed through Roll or Fold Form. Also BIM-BB+RR can be equipped with PLC and Data Logging Systems for inspection report generation.

Features

Fabric inlet from roll or flat fold Form

Fabric outlet in roll form

Batching Arm with Pneumatic Cylinders

Auto-Stop at feed, if machine running out of fabric

Laminated Inspection Table

Top & Bottom Lights

Length Counter Meter for fabric length measurement

Sensor type Edge Guiding for presentable roll (No Air or Oil required)

Full Length reversing for rechecking with Jog/Inching operation

S.S. Scroll Roller for creaseless fabric roll

Adjustable roll Compactness

Dancing Roller Mechanism for Multi Drive Synchronisation

Guide Rollers with Smooth finish

Wooden Platform for Operator

A.C. Inverter Drive with In-built software (Low electricity consumption)

Imported rubber emery on winding roll for extra life

Variable speed from 0 - 60 meter/min.

Italian geared-motors on all positive driven rolls

Utility Tray and Single phase Switch box is provided

Safety sensors and Emergency stop is provided

|