Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Lime Rotary Kiln-cnxb0613

Features and Benefits of XingBang Lime Rotary Kiln:

1,High production Capacity

2,Effective improve the firing Temperature,lower fuel consumption

3,Fully from the normal preheating temperature

4,Can directly calcining 10-15 fine fraction limestone

5,Widely range to row and fuel materials,unobstructed air,eduction sulfur smoke timely;

6,Stable quality.

Basic Structure and main subordinate equipment of lime kiln:

The lime kiln mainly consists of kiln body,loading device, burning deice,unloading device,electronic appliance,duct collection,etc.Different lime kilns have different structures,their process flow are almost the same.But the equipment value has big distinction,of course the result are different.

Flow Chart of Lime Rotary Kiln:

1, Qualified limestone deposited in the stock bin and transported into the top bunker of the preheater by the elevator.

2, At the top bunker of the preheater there are 2 material place control machines to control the feed,then the limestone were evenly distributed to the interior of the preheater through the material feeding tube.

3,When preheated to 900℃ by the 1150℃ kiln gas.About 30% decomposition,the hydraulic push the push rod in rotary kiln

4,The limestone in the rotary kiln was decomposition into Cao and CO2 with the help of high temperature,the generation limestone after decomposition enter into the cooler.

5,In the cooler,they were cooled to 100℃ by the cold air,then discharge.

6,The 600℃ heat hot air enter into the kiln mixed with the coal gas,then burning.

7,The waste gas mixed cold wind enter into the bag filter by th draft fan,then the exhaust fan transported to the chimney.

8,Out of the cooler lime,through vibrating feeder,chain conveyor,bucket elevator,belt conveyor were transport to the finished-parts storage.

http://www.china-xingbang.com/12.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Metallurgy Pellet Rotary Kiln-cnxb0613

Summary to Xingbang Metallurgy Pellet Rotary Kiln:

1,Kiln bode is made of high-quality carbon steel or ally calm;

2,Tyre,wheel,open type gear,all with alloy cast steel;

3,Sliding bearing adopt a large gap not scratch-pad bearing;

4,Hardened reducer,flexible diaphragm coupling,DC motor drive;

5,The head and end of kiln with scale layer and compression seal cylinder;

6,Equipment with slow drive.

Features and Benefits of Metallurgy Rotary Kiln;

1,This new type of metallurgy rotary kiln with the features of sample structure,convenience and reliable production process control,less wearing parts,high rates,high production capacity.

2,Metallurgy pellet rotary kiln is mainly used in metallurgy industry,poor iron ore magnetic roasting of iron and steel;chromium,nickel,iron ore

3,roasting;refractory high-metallurgical ore roasting plant and aluminum

4,roasting clinker,aluminum hydroxide;baking chrome ore and chemical chrome

5,ore and other materials.

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Mobile Crushing Station-cnxb0613

Characteristics of Mobile Crushing Station:Applied to multistage crush large materials;Screen the discharges according to their different specifications;Widely used to mine, building material, highway, rail way and hydropower industries, etc;Finish crushing and screening operations at one timeWorking Principle of Mobile Crushing Station:The Mobile Stone Crusher(mobile crushing and screening plants) is composed of primary crushing and screening station and secondary one, belt conveyor, etc. Every crushing station is an independent working unit, they can respectively assume their different responsibility, and the belt conveyer is responsible for material transmitting and piling up between each crushing station.arameters of Tire-type Mobile Impact Crusher Station.Features of Mobile Crushing Station:1.Reasonable matching; 2.Unobstructed discharge all line; 3.Reliable working, convenient operation; 4.High efficiency and saving energy; 5.The mobility is very good,so it can extend with the raw material places or the construction place, and it can also make multiple matching, get to different product requirements. ;http://www.china-xingbang.com/34.htmlBall MillRotary KilnJaw CrusherStone CrusherContact person: Luz LiuTel: 0086-371-67996871 0086-371-67996872E-mail: [email protected]: [email protected]: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Ring Hammer Crusher-cnxb0613

Characteristics of Ring Hammer Crusher:

A kind of impact rotor type crusher with a ring hammer;

Widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry;

Crushing ratio of 4-6 and the shape of final product is even;

To crush high hardness, mid hardness and soft rocks and ores.

Working Principle of Ring Hammer Crusher:

Ring hammer crusher mainly makes use of the impact effect to crush materials. The crushing process is roughly like this: when the materials enter the crusher, they are crushed by the high speeding ring hammer. The crushed materials gain energy from the ring hammer, rush to the crushing board at high speed, and crashed at second time. At the same time the materials bump with each other, and are repeatedly cracked. The material smaller than the grate bar gap are discharged, while larger ones on the grate bar are impacted, grinded, squeezed again to be crashed by the hammer, at last the materials are extruded by the hammer from the gap to obtain products with the required size.The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

Working Process of Ring Hammer Crusher:

When material enters into the crusher, it can be crushed by the ring hammer which is revolved by the high-speed motor, at the same time material obtained the kinetic energy and rushed at the impact plate receiving the second crushing process, then falls on the screen sieve and be cut, extruded, and grinded by the ring hammer. At last the materials that come up to the standard can be discharged by the machine. Material can’t be crushed enters into the metal collector and should be eliminated regularly. Through replacement of sieve plate, discharge size of materials can be adjusted. Gap between rotor and sieve plate can be adjusted by the mechanism.

http://www.china-xingbang.com/36.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

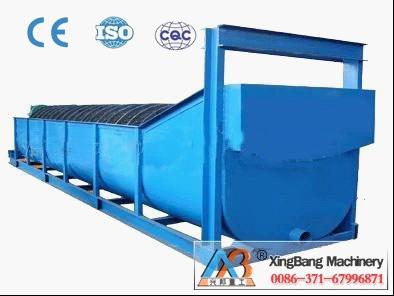

Spiral Classifier-cnxb0613

Features and usage of Xingbang Spiral Classifier:Energy saving;Heavy duty, rugged construction;Powerful self-contained spiral lifting deviceContinuous spiral rakingOptimal particle size range 800 to 75 micronsTechnical Process of Spiral Classifier:There are two types of spiral classifier, single spiral classifer and double spiral classifier. According to the spiral blade at the flooding end, there are two types: High weir type: the top side of spiral blade is higher than the flooding level and the center of blade is lower than the flooding level. This type is used for classification of the ore with flooding size between 0.083-0.15mm Immersed weir type: This type is used for classification of the ore with flooding size between 0.15-0.07mm. .http://www.china-xingbang.com/23.htmlBall MillRotary KilnJaw CrusherStone CrusherContact person: Luz LiuTel: 0086-371-67996871 0086-371-67996872E-mail: [email protected]: [email protected]: http://www.china-xingbang.com/

|