Supllier Listing

List of Suppliers

| Logo | Company Name | Product | Pattern | Feature | Type | End Use | Description | Store Front |

|---|---|---|---|---|---|---|---|---|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Grate Ball Mill-cnxb0613

Characteristics of Grate Ball Mill:

The hollow axis adopts the cast steel;

The lining can be replaced;

Rotating adopts casting rolling gear;

The barrel body is wearable;

The machine runs smoothly;

Works realiably.

Working Process of Grate Ball Mill;

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

Working Principle of Grate Ball Mill

This machine is a horizontal cylinder rotary device which can be installed on base ground once and forever. The main bearing with double roller bearings can save energy by 30%, improve fineness, and increase processing energy by 15-20%. Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

http://www.china-xingbang.com/2.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Intermittent Ball Mill-cnxb0613

Characteristics of Intermittent Ball Mill:

An essential recrushing equipment;

A horizontal rotary cylinder device;

Rotating big gear adopts casting rolling gear;

Widely used various industry;

Performs dry or wet grinding on all kinds of ores;

Works realiably.

Working Process of Intermittent Ball Mill:

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

Working Principle of Intermittent Ball Mill

Through material hollow shaft spiral the material is sent to the first mill chamber, in which there are ladder liner or corrugated linings, with steel balls of different specifications in it. When cylinder rotating, centrifugal force will produce steel ball fall down from a certain height, thus impacting and grinding the materials. After coarse grinding in the first chamber, materials enter into the second chamber through a single diaphragm. In this warehouse with flat lining board and steel balls in it, materials are further grinded.

http://www.china-xingbang.com/4.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Jaw Crusher-cnxb0613

Characteristics of Jaw Crusher:

Used as the primary crusher to the medium size crushing of various ores and large-size materials;

Widely used in stone mining, metallurgy industry, building material, highway, railway, and chemical industry;

Crushing ratio of 4-6 and the shape of final product is even;

To crush high hardness, mid hardness and soft rocks and ores.

h high hardness, mid hardness and soft rocks and ores.

Working Principle of Jaw Crusher:

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

The motor transmits power through belt, drives the moving jaw to do periodic motion towards the fixed jaw by the eccentric shaft. The angle between toggle plate and moving jaw plate increases when moving jaw moves . So the moving jaw moves towards the fixed jaw. The stuff will be crushed in this process. The angle between toggle plate and moving jaw decreases when moving jaw moves down, the moving jaw moves leaves fixed jaw by pulling rod and spring, the final crushed stuff will be discharged from the outlet.

Features of Jaw Crusher:

1.High reliability;

2.Flexible capacity;

3.Simple structure and easy to operate;

4.Over-loading protection;

5.Easy replacement of wear and spare parts;

6.Long service time

http://www.china-xingbang.com/32.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

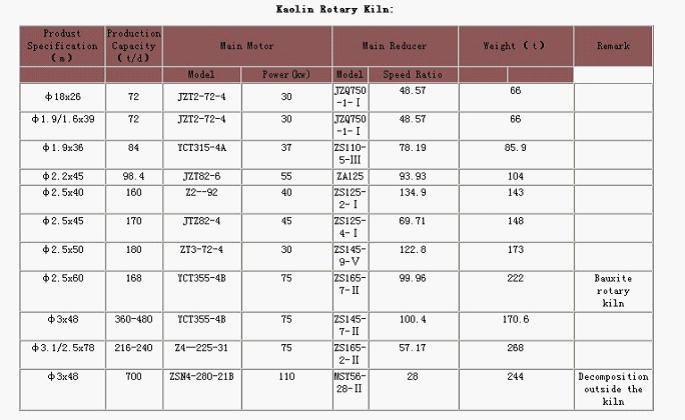

Kaolin Rotary Kiln-cnxb0613

Features and Benefits of Xingbang Kaolin Rotary Kiln:

1,Mature and advanced calcination technology;

2,Low energy consumption and high output Calcining technology;

3,Productions by dehydration,decarbonization whitening,with stable performance;

4,Widely used for paper, painting and other industries;

5,Represents the direction of fine calcined kaolin technology development;

Introduction to the Kaolin Kiln;

Kaolin rotary kiln also called bauxite rotary kiln,magnesia rotary kiln,zinc oxide rotary kilnKaolin with the features of high white content,soft texture, easy to disperse and suspend in the water, fine plasticity, high cohesive property, good electric insulation property; excellent anti-acid solubility, lower base exchange capacity, and pretty goodInternally heated rotary kiln calcining superfine kaolin by medium temperature(950 degree celsius-1050 degree celsius), the technology being maturity and advancement inland, is a leader in the superfine kaolin calcining technology which is energy-saving and of high production.

http://www.china-xingbang.com/24.html

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|

|

|

XingBang Heavy Industry Machinery Co., LTD

|

Sliver cansand springs

|

|

|

|

|

Laterite-Nickel ore kiln-cnxb0613

The technics of production nickel by rotary kiln:

1,The main energy for smelting of coal,instead of expensive energy of coke or electricity;

2,Freedom of choice of raw materials,use a variety of laterite in southeast Asia;

3,The production of high quality and high nickel-nickel-iron(containing Ni20 % or so) can be directly used as the raw materials stainless steel.;

4,At the same time as the cooling agent when melting steel

Introduction to the Laterite:

The name laterite is used to describe the weathering product of ferruginous rock exposed to strongly oxidizing and leaching conditions, usually in tropical and subtropical regionsNickel is a slightly yellow-white metal is a kind of magnetic of transition metals.The application of nickel is the corrosion resistance,Adding nickel alloy can enhance alloy corrosion resistance.the most widely used application of nickel is the fields of stainless steel and alloy production fields.About two-third of nickel used in stainless steel production,so the stainless steel industries to nickel consumption in the influence of the first l a.Nickel in the main functions of stainless steel is that it changes the steel crystal structure.

Smelting process methods:

1,Direction reduction method of the rotary kiln

2,Blast furnace process

3,The blast furnace process

4,Electric carbothermic process

5,Electro silicothermic process

Process Description of Rotary Kiln production of nickel-iron:

Large-scale rotary kiln is the key equipment in firing reduction smelting process.Ore after drying put into rotary kiln,,when heated to 800 ℃,After the removal of mineral water and surface water of crystallization,and partially reduced ore iron,nickel and cobalt oxide,into the furnace.

The development of nickel Smelting:

Used in our country by clay court holds nickel ore smelting nickel cast iron, stainless steel production materials constitute an important change, change the global stainless steel production materials supply and demand of nickel pattern, also changed the world stainless steel industry development pattern. The use of low-quality low-cost laterite nickel ore and minerals resources,in line with resource-saving trend of historical development,has opened a new charter in the history of China's stainless steel production. Currently,the low-grand blast furnace capacity is already saturated the market size and speed up the development of more than 10%grade of the roatry kiln process,can further expand the fire nickel ore market capacity. XingBang heavy industry to adapt the new way to smelting quality nickel ore has obtained high quality market and user recognition. Welcome all the customer to come to visit, investigate!

Ball Mill

Rotary Kiln

Jaw Crusher

Stone Crusher

Contact person: Luz Liu

Tel: 0086-371-67996871 0086-371-67996872

E-mail: [email protected]

MSN: [email protected]

WEB: http://www.china-xingbang.com/

|