World's first silk based electronic textile manufacturing tech developed

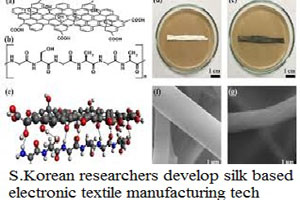

YarnsandFibers News Bureau 2016-12-13 10:00:00 – SeoulThe world’s first silk based electronic textile manufacturing technology developed based on graphene oxide coating on silk and requires no adhesive. The technology is being developed by the South Korean research team lead by Incheon University professor Kim Byeong-hoon and Inha University professor Jin Hyeong-joon. This was announced by the National Research Foundation of Korea on December 12.

The research team focused on the properties of silk, that is, the ease of hydrogen bonding and high-temperature resistance. It succeeded in graphene oxide coating without a medium such as an expensive adhesive by repeatedly dipping silk in a graphene oxide solution and drying it. In addition, the team accelerated the process of reduction into an electronic textile by using heat.

The team’s silk-based electronic textile showed little deformation even after washing and bending while maintaining an electric conductivity of approximately 10 S/m comparable to those of existing ones. In other words, the textile can be produced with its performance intact, at a lower cost and within a shorter period of time.

According to the research team, its technique is expected to contribute to the development of flexible display panels, wearable gadgets, sensors detecting harmful substances and so on.

Electronics textiles have been applied to combat uniforms, biometric shirts, wearable computers, etc.

The commercial use of this type of textiles due to high manufacturing costs and complex manufacturing process has shown little progress

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide