Walmart, Unspun collaborate on sustainable garment production

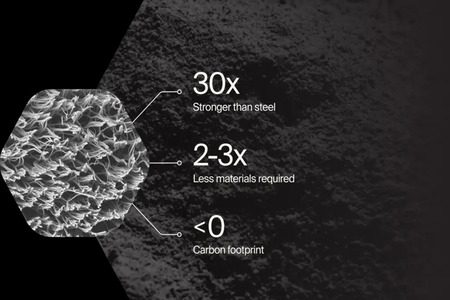

YarnsandFibers News Bureau 2024-03-14 17:16:39 – USARetail giant Walmart has announced a new pilot project in partnership with textile innovator Unspun, aiming to reduce the environmental impact of clothing production. The collaboration will explore the use of Unspun's 3D weaving machines to manufacture workwear-style pants for a Walmart house brand. Based in Oakland, California, Unspun is known for developing Vega, the world's first 3D weaving technology, which efficiently converts yarn into garments.

If successful, the project could significantly decrease the environmental footprint of clothing production, offering a more sustainable approach to meeting fashion demands. This initiative aligns with both companies' shared goal of revitalizing textile manufacturing in the United States, while addressing concerns about waste in the apparel industry.

Andrea Albright, Walmart's executive vice president for sourcing, expressed enthusiasm for the collaboration, highlighting Walmart's commitment to innovation in its supply chain. The partnership with Unspun has the potential to create more skilled jobs in the US, meet consumer demand for locally made garments, and enhance transparency and sustainability in Walmart's apparel supply chain.

The project is part of Unspun's larger plans to establish multiple microsites for manufacturing on or near-shore, in partnership with a manufacturing partner. It also supports Unspun's goal to install over 350 Vega machines across North America by 2030, reaching an annual production capacity of about 10 million units.

Shuo Yang from Lowercarbon Capital, a leading climate-tech investor, expressed optimism about Unspun's technology, noting its potential to revolutionize garment manufacturing. The collaboration with Walmart is seen as a significant step towards a more sustainable future in manufacturing.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide