VTT develops pilot factory for sustainable smart wearable patches

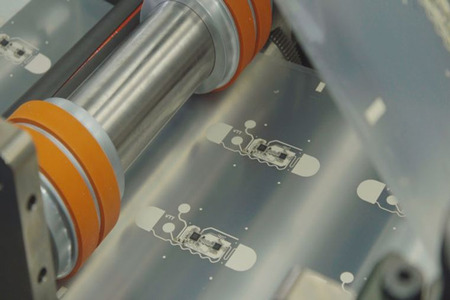

YarnsandFibers News Bureau 2024-05-21 17:25:46 – FinlandThe VTT Technical Research Centre of Finland has developed a pilot factory for roll-to-roll production of smart wearable patches, which will be showcased at the Future of Electronics Reshaped USA conference in Boston on June 13-14. VTT's sustainable electrocardiogram (ECG) is made of a nanocellulose e-skin printed with carbon conductors and sensing electrodes. The device is modular, allowing electronic components to be easily removed and reused.

"Wearable sensor patches offer novel opportunities for many healthcare and wellness applications," says Antti Kemppainen, VTT's sensing solutions manager. "For comfort and reliability, they need to be flexible, soft, conformable, and even stretchable. Printed and hybrid electronics enable the use of almost any substrate for next-generation wearables, including recycled, biobased, or biodegradable materials."

Component assembly can be performed using a high-throughput pick-and-place line for low-temperature soldering or adhesive bonding, a flip-chip high-precision and bare-die assembly line, and extensive converting and post-processing capabilities, including lamination, cutting, and an injection molding machine with a roll feeder for overmolded electronics.

"VTT's experienced crew can offer a fast path from proof of concept feasibility to scalable continuous web manufacturing," says Kemppainen. "Alternatively, we can address specific technical challenges or process bottlenecks."

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide