Valvan innovates textile recycling with automated sorting machines

YarnsandFibers News Bureau 2023-09-28 18:14:04 – BelgiumBelgian company Valvan has developed two machines, Fibersort and Trimclean, to enhance textile recycling. Fibersort can process one garment per second, equivalent to about 1,200 kilograms per hour. It uses 3D and RGB cameras to determine the item's size, color, and fabric type, especially focusing on identifying the fibers the garment is made of. This is crucial for high-quality textile recycling.

Currently, only 0.6% of discarded textiles are recycled into new clothes, but the potential for recycling is vast. Starting in 2025, European member states are mandated to collect half of all textile waste. Fibersort helps textile collectors identify the composition of garments, distinguishing between fabrics like cotton or blends, aiding in efficient recycling methods such as mechanical, thermomechanical, or chemical.

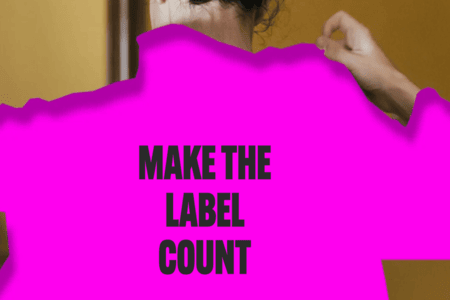

Clothing labels are often inaccurate in providing information about garment composition. Research by Dutch NGO Circle Economy revealed that 40% of clothing labels had incorrect details about the fabric composition. This lack of accurate information poses challenges in recycling, especially for blends that are more difficult to recycle.

The machines by Valvan aim to address impending legislation on textile collection and eco-design by advancing textile recycling processes, aligning with the growing need for sustainable waste management in the textile industry.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide