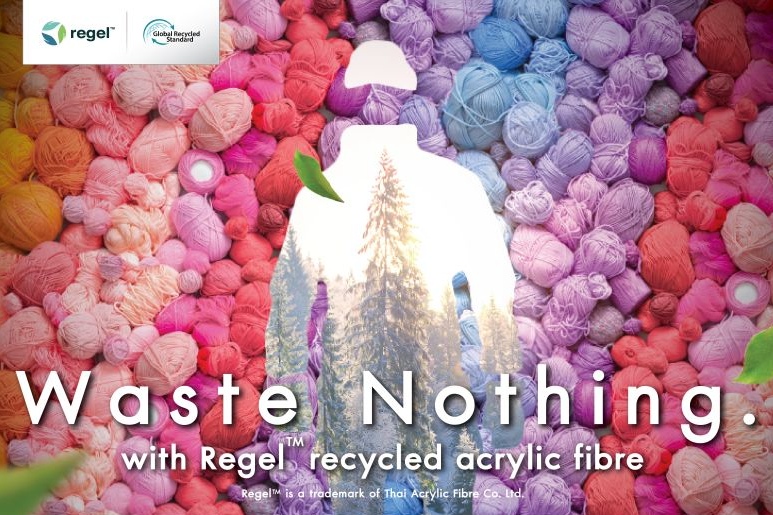

Regel

The Aditya Birla Group‘s Thai Acrylic Fibre Co. Ltd. (TAF) has launched a recycled acrylic fiber, Regel™. The new fiber is manufactured from recycled acrylic waste and has already been certified by the Global Recycled Standards or GRS.

TAF created this fiber in response to the increased demand for sustainable fashion items from consumers, brands, and retailers throughout the world. Recycling pre-consumer, post-consumer, and in-process waste to make new products are one of the most preferred and prevalent ways to reduce environmental impact.

Thomas Varghese, Business Head – Textiles, Aditya Birla Group, said that Regel™ is a unique innovation as it is one of the first successful commercialization of acrylic fiber produced by recycling waste. Regel™ was conceived as a result of their conversations with leading fashion retailers who are eager to replace traditional fibers with materials that have a higher sustainability index. Forming the technique and technology for recycling acrylic waste took them roughly 1.5 years of rigorous R&D.

Siddhartha Chakrabarti, Chief Research & Technology Officer, TAF, said that Regel™ fiber is made up of 50% recycled waste and 50% virgin polymer, with the possibility to increase the recycled content even more. Regul™ technology is unique in that it provides a homogenous blending of both recycled and virgin polymer while keeping the quality and other practical benefits of acrylic fiber, such as warmth, comfort, and brilliant colors. This is a key advantage of Regel™ fiber over other techniques like mechanical shredding, where content, quality, and color selection are limited, as the behavior and properties of Regel™ fiber are identical to fresh acrylic fiber.

Regel™ fiber is commercially accessible and manufactured at TAF’s Saraburi acrylic fiber factory.

Modern Meadow proudly announced that Karmuel Young, founder of the Hong Kong-based menswear label, integrated the INNOVERA biomaterial into his…

XYXX has introduced its latest innovation in men’s innerwear, featuring Tencel-enhanced Tactel fabric that enables fabric to dry up to…

Dhana Inc. has partnered with Accelerating Circularity Inc. (ACP), a nonprofit organization focused on developing textile-to-textile recycling systems.

Circulose has entered a strategic partnership with Tangshan Sanyou Chemical Fiber, marking a major step toward the commercialization and scaling…

LebaTex has launched a new faux leather collection featuring over 100 unique colors and textures, including polyurethane, vinyl, and silicone…

Gabriela Hearst has introduced eco-friendly sneaker line, named "Ohio," made from 30% recycled materials, reflecting the brand’s commitment to sustainability.