SHEIN expands cool transfer denim printing

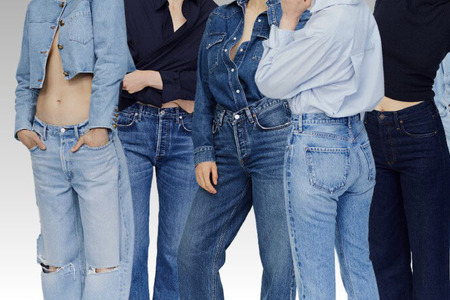

YarnsandFibers News Bureau 2025-01-08 14:34:19 – SingaporeSHEIN is revolutionizing denim production by expanding its use of Cool Transfer Denim Printing, a technology that reduces water and energy consumption while simplifying the production process.

Conventional denim manufacturing is resource-intensive, requiring significant amounts of water and energy for dyeing, bleaching, and washing. To address these challenges, SHEIN partnered with NTX® in 2021 to introduce Cool Transfer Denim Printing. This advanced method reduces resource consumption and streamlines production while ensuring precision and efficiency.

The process uses digital printers with reactive ink to create denim textures, patterns, and effects on transfer film, which are then imprinted onto white denim fabric using cold transfer equipment. This technique replicates features like faded finishes, whiskering, and vintage-worn effects. Verified by Bureau Veritas in 2023, the method cuts water usage by 70.5% compared to traditional denim washing processes.

Beyond conserving resources, Cool Transfer Denim Printing eliminates the use of harmful chemicals like chlorine and caustic soda, reducing workers’ exposure to hazardous substances. This innovation not only promotes environmental sustainability but also fosters safer working conditions for those involved in denim production.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide