Researchers develop sustainable carbon fiber manufacturing process

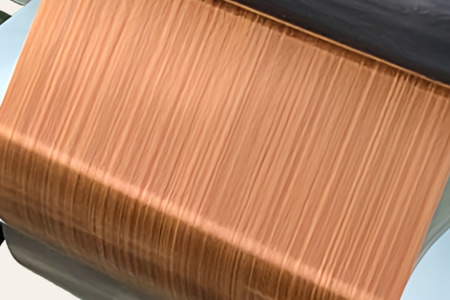

YarnsandFibers News Bureau 2025-03-11 16:06:54 – IrelandA research team at the University of Limerick (UL) has introduced a groundbreaking method for producing carbon fiber through their CARBOWAVE project. This approach utilizes plasma and microwave heating, cutting energy consumption by 70% while maintaining the material’s strength.

For years, scientists have explored alternatives to polyacrylonitrile (PAN), a synthetic polymer, including biobased polymers like lignin. However, these substitutes have struggled to match the strength and durability of PAN-based carbon fibers. The need for a more efficient manufacturing process has led researchers to explore alternative heating methods, culminating in the innovative CARBOWAVE approach.

This method eliminates the need for prolonged high-temperature treatments, making carbon fiber production faster and more efficient. Additionally, microwave heating allows for selective heating, improved energy transfer, and greater automation potential, further enhancing the manufacturing process.

Professor Maurice Collins, the project’s lead investigator, highlighted the importance of this breakthrough: “Europe’s reliance on energy-intensive processes has been a major challenge for sustainability. CARBOWAVE presents a solution by making carbon fiber production both more sustainable and cost-effective.”

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide