RapidMade launches innovative thermoformable carbon fiber

YarnsandFibers News Bureau 2025-01-30 16:18:58 – USARapidMade, a company specializing in 3D printing, thermoforming, machining, and engineering services, has launched Aerolite in partnership with West Lake Plastics. This new thermoformable carbon fiber solution is designed to speed up production while reducing costs, all while maintaining high performance and visual appeal.

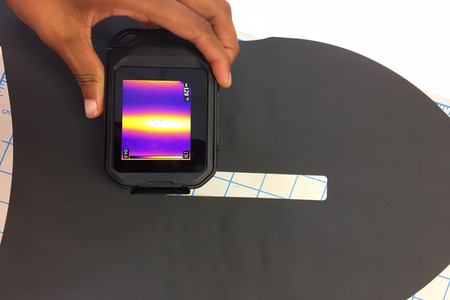

Aerolite carbon fiber offers several benefits. According to RapidMade, thermoforming shortens traditional curing times from hours to just two minutes per part, resulting in 97% faster production speeds. The automated process also removes the need for labor-intensive manual layering, cutting down labor and tooling costs by 75%. Additionally, automated forming and CNC trimming enhance consistency, ensuring high-quality parts with minimal defects and waste.

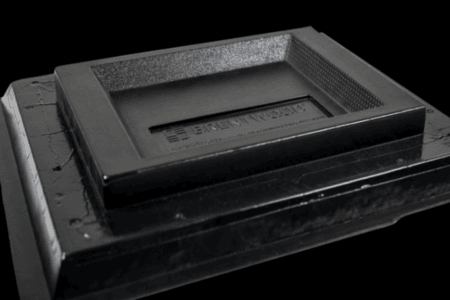

Aerolite is available in two variants: 15% and 30% infill, with thickness options of 1.5 mm (0.060") and 2.5 mm (0.100"). It boasts a tensile strength of up to 200 MPa and a flexural strength of up to 253 MPa, making it seven times stiffer than polycarbonate.

Aerolite is well-suited for industries such as automotive, aerospace, robotics, and heavy manufacturing. It allows for complex designs and high customization while maintaining structural strength. Its design guidelines ensure easy adoption into existing production processes, making it a practical solution for manufacturers looking for efficiency and durability.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide