Porex launches technological platforms to assist brands develop sustainable products

YarnsandFibers News Bureau 2020-11-27 12:34:15 – USAPorex has announced the launch of its sustainable product development capabilities to aid manufacturers with early product development across three technology platforms.

The brands can now work with Porex’s experts in material innovation and leveraging the latest technologies for sintered particles, bonded fibre and open-cell foam, to create more sustainable products that can be utilised in various applications such as, care, cosmetics, diagnostics, consumer, healthcare and industrial markets.

The sustainable product development initiative is a part of Porex’s global sustainability program that focuses on four areas, material innovation, supply chain, community and waste and recycling. The announcement kick starts the first pillar off Porex’s first area of focus, material innovation. This area mainly focuses on setting specific goals to reduce the company’s use of virgin plastics in new products by 25 per cent by 2025.

Avi Robbins, Vice President, Global Product Development and R&D at Porex, stated that they are committed to long-term sustainability and adoption of green business practices. Robbins stated that the company had already been leading the efforts in sustainability by utilising recycled content such as resins from PE and PET packaging in innovative ways. The Vice President added that their product development capacities only intensify their efforts to reduce environmental footprint and support customers by providing innovation and helping them meet their own sustainability goals.

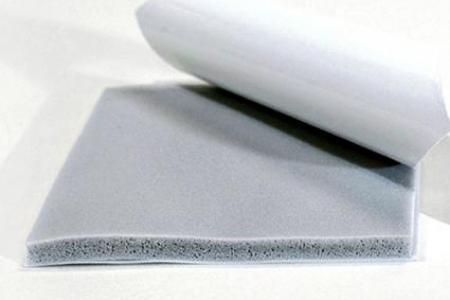

The sustainable product development will cover all three porous polymer technology platforms: sintered particles, bonded fibre and open-cell foam. Porex selects the optimum sustainable material based on the customer’s unique product application and collaborates with them to develop the desired product. Some of the components that fall under the umbrella of the brand’s platform are recycled PE and polyester fibre (PET), biodegradable PE, PE fibre, and PET fibre, and bio-based polyurethane.

Each of Porex’s technology platforms serves a range of markets and product segments. Sintered particles feature well-defined, complex 3D geometries suitable for filters or wicks used in plug-in air fresheners or insecticide applications. Bonded fibre solutions feature flexible 2D geometries that provide wicking, absorption and release functions essential for diagnostic applications like, collecting materials utilised for saliva- and urine-based tests and reservoirs for writing instruments. Open-cell foam materials are highly absorptive and can be made antimicrobial.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide