Polartec removes potentially harmful PFAs from its range of performance fabrics

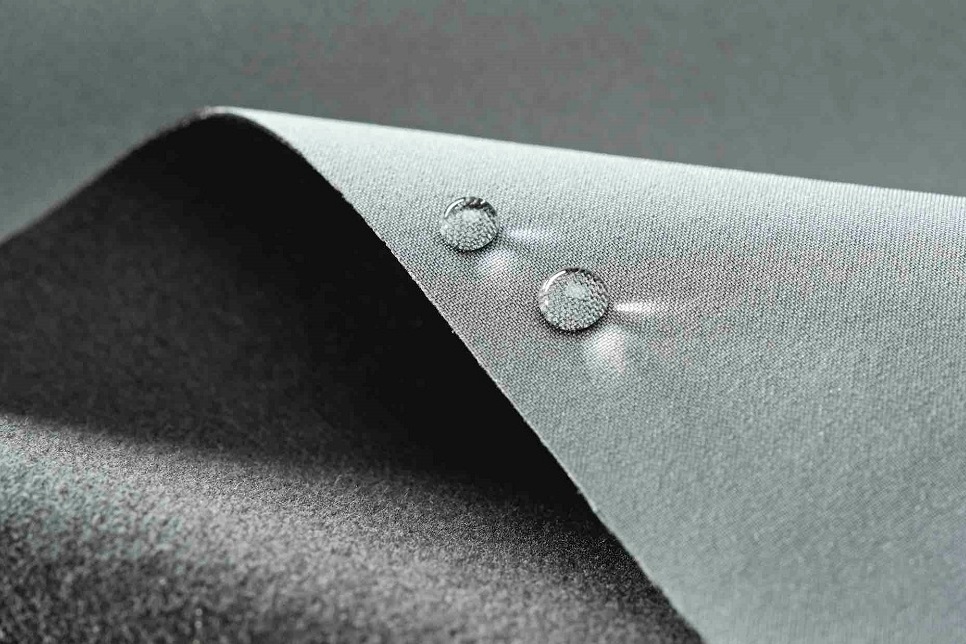

YarnsandFibers News Bureau 2021-07-14 07:48:54 – USAPolartec®, a Milliken & Company brand that develops innovative and sustainable textile solutions, has announced the removal of per- and poly-fluoroalkyl substances (PFAS) from its DWR (durable water repellent) treatments throughout its entire portfolio of performance fabrics.

Polartec's innovative non-PFAS treatment, which has no effect on durability or water repellency, is the latest in the company's expanding EcoEngineeringTM iSeries initiative.

Polartec focused on performance and lifespan as it attempted to remove PFAS from its DWR treatments as part of its environmental initiatives. Hardface®, Power Shield®, Power Shield® Pro, NeoShell®, and Windbloc® products will all benefit from this enhanced weather protection fabric treatment. The technology will also be applied to fleece and insulation treatments, allowing for better moisture control on items such as Thermal Pro® and Alpha®.

Mike Rose, Polartec vice president of Product Development, said that the trial results have beyond even their expectations. From a water repellency or durability viewpoint, there is no loss of performance.”

Polartec president Steve Layton said that achieving non-PFAS treatments within their product portfolio is a key milestone in their commitment to sustainably manufactured performance textiles. It's the latest step in their quest to make Polartec even more sustainable.

Polartec has established itself as the world's leading innovator of performance textiles built for all circumstances throughout the course of its 30-year existence. The brand's commitment to ecologically friendly products continues to propel the industry ahead.

Sustainable science is the driving force behind the brand's innovation, from inventing the process of turning post-consumer plastic into performance fabrics and leading the use of recycled content across all categories — to innovating products with non-PFAS DWR treatments and leading the way in circularity.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide