If anyone doubts the staying power of cotton, consider that it was used 7,000 years ago for clothing in Ancient India, according to “The History of Clothing.” Its popularity has only continued, as modern performance technology has enhanced cotton’s natural properties so brands and designers can meet consumer demand for the fiber.

Nanotex, a leading provider of nanotechnology solutions for textiles, has a number of innovations that are applicable to cotton, said Kathryn Czuchra, marketing manager.

“It is an amazing fiber that we like to work with,” Czuchra said. “Thanks to our patented formulas, Nanotex blocks stains, prevents wrinkles and keeps moisture out while not allowing odors in. Whether you’re at home, the office or out-and-about, Nanotex lets you live, work and play without worry.”

Designers and manufacturers who want inspiration and direction regarding technical cotton fabrics can turn to Cotton Incorporated’s FABRICAST™ Collection. This series of cotton and cotton-rich fabrics was developed by the Product Development Team at Cotton Incorporated’s Research and Development Center, and highlight new and interesting yarns, unique weaving and knitting constructions, dyeing and finishing techniques, and fabric performance technologies.

The FABRICAST™ Collection highlights cotton materials that work in a variety of categories, from outerwear to shirtings to activewear. For instance, the diamond matelassé is a quilted, cotton-rich woven that offers weather-shield properties. A subtly iridescent surface gives it style appeal, while STORM COTTON™ technology keeps it water resistant, making it a great option for outdoor jackets with the natural feel of cotton. And a single-knit, 100 percent jacquard features a ruffling blister effect, which provides excellent insulative qualities due to the densely constructed ruffles. Those ruffles can be worn against the skin for insulation, or to the outside for a fashion effect.

Another piece from the FABRICAST™ entry is the satin fabric that is 98 percent cotton with 2 percent stretch. The fabric has both a luxurious surface sheen as well as moisture management properties, making it a men’s- and women’s wear option for both fashion and performance garments.

Along with its STORM COTTON™ technology, Cotton Incorporated has developed several other technologies that enhance cotton’s natural performance features. The TransDRY® technology maintains cotton’s comfort and softness while adding moisture management, making it ideal for cotton activewear. Another popular choice for activewear is Cotton Incorporated’s WICKING WINDOWS™ technology. This unique performance technology transfers moisture away from the skin and to the outside of the fabric, making for a drier, more comfortable experience for the wearer.

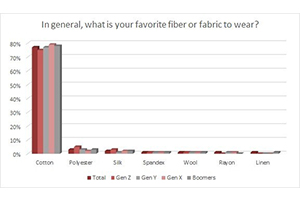

Brands that use performance cotton in their designs stand to benefit because already, more than three-quarters of all consumers (78 percent) say cotton is their favorite fabric to wear, according to the Cotton Incorporated Lifestyle Monitor™ Survey. Further, 63 percent say they would feel more loyal to a brand that offers clothes made of natural fibers. Compared to manmade fiber clothing, more than seven in 10 consumers say cotton clothing is the most comfortable (84 percent), softest (84 percent), sustainable (82 percent), and quality (75 percent). It stands to reason that enhanced cotton would be even more attractive to consumers.

“There’s a reason the highest-quality dress shirts are made with cotton for as long as they have been,” says Lawrence Hunt’s Jeff Schattner, founder of the cotton performance dress shirt company. “It all starts with the breathability of cotton. A good quality, lightweight cotton is one of the most breathable fabrics around. You cannot replicate the look and feel of cotton fabric on your body on a hot summer day.”

Lawrence Hunt’s “No Sweat” dress shirts are made of 100 percent cotton, and have the added benefit of sweat-wicking technology in the underarm area, making them “what you would wear for high pressure situations such as an interview, board meeting, sales call, etc.,” Schattner said.

Schattner developed his dress shirt after attending a summer wedding and realizing he was uncomfortably hot in his standard attire. The company now also offers its “Featherweight” shirt, made from super thin, soft and lightweight cotton that relies on the fiber’s natural performance features, like breathability and odor resistance.

“Our Featherweight shirts are perfect for casual Fridays or relaxing on the weekend,” Schattner said. “Ultimately, we want to provide everyone with the most comfortable professional apparel for any situation.”

Designers can mine the FABRICAST™ collection to discover a wide variety of enhancements to the natural fiber. Technologies include a 100 percent cotton lightweight oxford cloth that’s treated with STORM COTTON™ technology. This particular fabric provides a water-resistant finish that offers protection from rain, as well as light wind resistance. Another is a “double cloth” construction and features a blend of 82 percent cotton and 18 percent wool that enables the fabric to be lightweight and breathable due to the cotton, but with wool’s odor control and thermal properties.

The FABRICAST™ collection also includes a 100 percent cotton textured crepe fabric that plays up its environmentally friendly appeal: the fabric is left undyed to display the natural color of cotton. The minimal processing reduces water, time and energy, and reduces chemistry during processing. The same can be said for an all-natural cotton/wool sherpa. Blending wool with cotton allows for this pile fabric to pass flammability requirements. And again, minimal processing and a lack of dyeing make this an eco-friendly material.

The use of more environmentally conscious practices is one of the goals of the Ellen MacArthur Foundation, which recently released new guidelines to help denim companies reduce waste, eliminate pollution and eventually implement “circular” manufacturing practices. Part of “The Jeans Redesign” plan is the call for denim that is made from a minimum of 98 percent cellulose-based fibers, like cotton. This makes them more durable and increases recyclability.

Using more cotton in denim jeans would also appeal to more than seven in 10 consumers, who say “if I could spend my life in just one fiber, it would be cotton,” according to Monitor™ research. And Czuchra says with Nanotex technologies, its clients have the flexibility to tailor the innovations and enhancements for each cotton garment.

“We work with a wide variety of mills and retailers, developing apparel technologies for cotton,” she said. The company worked closely with Cotton Incorporated to develop its Nanotex® DRY INSIDE technology. “The benefit of our technology on cotton is we can enable the fabric to dry quickly while reducing fabric cling, chafing and irritation leaving the wearer comfortable and dry. Our DRY INSIDE technology takes cotton to the next level and becomes a performance fiber, which more brands are looking for to help promote the longevity of their garments.”

Such technologies will help the brands that use them stand out among the consumers who say they plan to seek out moisture management technology in their activewear (54 percent), intimates (52 percent) and casual wear (46 percent), according to the Monitor™ research.

The Monitor™ data also shows one-third of consumers or more plans to seek out water-repellent technology in their activewear (41 percent), casual wear (35 percent), and intimates (34 percent). And at least two in five consumers plan to seek out thermal-regulating technology in their activewear (49 percent), casualwear (43 percent), and intimates (40 percent).

Later this year, Nanotex is introducing NFORCE, an eco-friendly, at-home DIY laundry treatment that allows everyday clothes to repel spills and remain stain free.

“Nanotex technologies extend the useful life of garments,” Czuchra said. “Our patented technologies are permanently bonded to the fabric without sacrificing the natural qualities of the material. We have tested our technologies to perform over 30 home launderings—so brands and consumers will get a long lasting performance garment that feels good and looks good.”

Cotton Incorporated is a global resource for all things cotton. The research and promotion organization continues its near-50-year commitment to providing expertise and information on all aspects of the global cotton supply chain: from dirt to shirt—and beyond. Additional relevant information can be found at CottonLifestyleMonitor.com.

Courtesy: Weekly PriceWatch Report

Eugène Riconneaus is launching ER Ocean Recherche, an R&D center focused on creating ocean-sourced sustainable materials for the fashion industry.

In line with sustainable shift, material science brand Pangaia has introduced its (Gaia)Plnt Nylon capsule, a collection made entirely from…

Boi Knit Lab is redefining the landscape of knitwear and textile innovation through its seamless integration of research, design, and…

A groundbreaking project titled "Development of Specialised Firefighting Suit" aims to reduce India’s dependency on imports of high-performance protective gear.

Eastman has unveiled Naia On The Move, a high-performance, sustainable fibre engineered for activewear and urban lifestyles expands the Naia’s…

X Tech has partnered with Fulgar to unveil a new line of performance garments crafted with Q-Skin, a cutting-edge polyamide…