Mimaki Europe introduces Tx330 series direct-to-textile printers

YarnsandFibers News Bureau 2025-02-27 17:15:36 – GermanyMimaki Europe, a leading manufacturer of industrial inkjet printers, cutting plotters, and 3D printers, has unveiled two new direct-to-textile printers, the Tx330-1800 and Tx330-1800B. The Tx330 Series expands textile printing capabilities, allowing users to print on various materials with minimal wastewater. The Tx330 Series offers a space-efficient solution, making it ideal for users with limited production space

Designed to promote waterless, high-quality textile printing, the Tx330 Series caters to apparel manufacturers seeking both sustainability and premium print quality. These printers support dual ink sets, allowing users to switch between textile pigment inks and dye sublimation inks. These advanced printing solutions simplify the process with direct printing and heat fixation, eliminating the need for complex water supply and wastewater treatment systems.

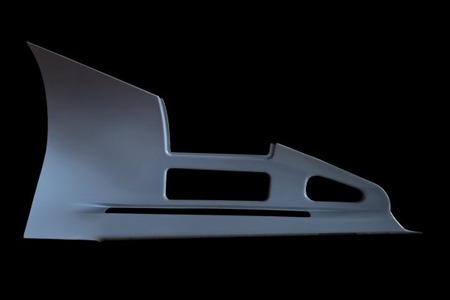

The Tx330-1800 model enables seamless printing on both fabric and paper within a single machine, making it ideal for textile signage and interior fabrics. The Tx330-1800B, on the other hand, features a space-saving belt conveyor, which ensures stable printing on stretchable, thick, and thin fabrics commonly used in apparel production.

Arjen Evertse, General Manager Sales EMEA at Mimaki Europe, stated, “The demand for locally produced, on-demand textile products is on the rise. With this in mind, we developed two user-friendly, versatile, and sustainable printers that enable businesses to incorporate textile printing in small spaces without sacrificing quality or functionality.”

The Tx330-1800 Series is powered by Mimaki’s “330 Engine,” ensuring sharp details, smooth color transitions, and high-density printing. This advanced technology delivers precise color accuracy and superior print quality, aligning with the performance standards of other models in the 330 Series.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide