Lalaland, Elastium to advance 3D-printed footwear

YarnsandFibers News Bureau 2024-10-11 18:10:20 – USALalaland, a leading footwear and leather goods factory based in Los Angeles, has partnered with 3D-printing innovator Elastium to enhance its production capabilities for performance shoes. This collaboration marks a significant step towards localized footwear manufacturing in the U.S., combining advanced 3D-printing technology with traditional shoemaking methods.

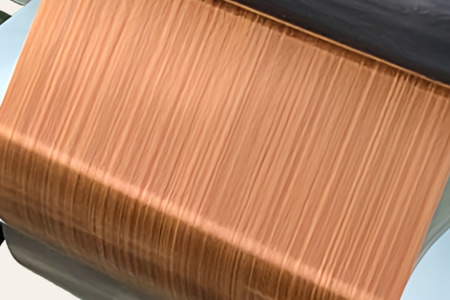

Elastium, founded by engineer Robert Karklinsh, has developed proprietary lightweight TPU materials and 3D-printing technology that allow for the production of footwear foams and uppers in Lalaland’s factory. These components are then assembled using standard construction processes, providing a scalable solution for onshore production.

Karklinsh emphasized the strategic decision to bring these capabilities to the U.S., which will enable athletic footwear brands to accelerate product development and reduce costs related to overseas production. The 3D-printing process eliminates the need for costly molds, allowing for faster turnaround times and no minimum order quantities.

The partnership’s first co-designed product, the Orca shoe, features 3D-printed uppers and foam midsoles, demonstrating the potential of integrating traditional and advanced technologies. Lalaland CEO Alex Zar, now a senior investor in Elastium, sees this collaboration as a way to revolutionize the footwear industry by improving both performance and sustainability in shoe production.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide