FS Innovations launch eco-friendly dying process called DOPHO-PLUS

YarnsandFibers News Bureau 2020-12-24 12:42:09 – South KoreaFS Innovation has announced the launch of the World’s first sustainable eco-friendly dyeing technology that saves water and energy in the fabric production process. This new innovation in the dying space also discharges less wastewater and fine dust.

The apparel and footwear industry is responsible for 8% of global greenhouse gas emissions, which is more than those from global aviation and shipping processes combined. This mainly happens in the production process in clothing materials due to the fact that, no matter how much organic natural fibres or recycled synthetic fibres are used to manufacture eco-friendly fabrics, they act as supplements along with dyes in water equal to 10 times the amount of the fabric when actually immersed and boiled.

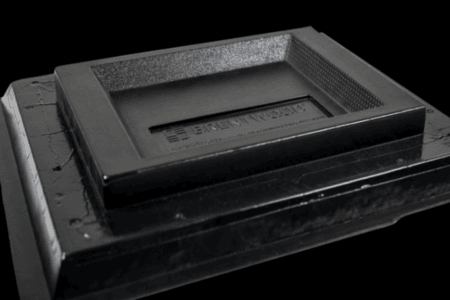

FS Innovation has innovated the world's first true eco-friendly magnetic field dyeing process equipment called DOPHO-PLUS. This new technology utilises smearing dyeing method, not a classic liquid dyeing method, which refers to simply dipping the fabric in existing dyes such as permeation and foam dyeing. The new eco-friendly innovation is high in productivity and low in cost that saves more than 70% of water and energy input compared to conventional methods in the fabric production process. It also reduced the wastewater discharge and fine dust by 70%. The new application works by putting a permanent magnet inside the mangle inside the 'canal blade' and the take-up roller and coating a thin coating film (fluid film) on the fabric surface with the magnetic field (electromagnetic force) generated here. The new system also has a provision that allows the user to adjust the required amount or the amount of dye or processing liquid as desired. In the case of the existing padding mangle method, the 6~7% of defect rate happens due to factors such as biaxial deviation due to tension generated when the fabric passes through the mangle, dyeing deviation at the beginning and end of the fabric, dye spot due to excessive dyeing, and concentration deviation due to reverse flow of dye. The new technology, however, ensures the canal blade and take roller are completely grounded and driven based on magnetic field technology. The dye is also applied evenly and achieves a defect rate of 0%.

The company has a patent for liquid coating for fabrics and for tensionless vacuum suction washing device, that prevents defects due to tension applied to the dyed fabric. The technology is suitable for completely removing impurities in the fabric, including oil in the spandex yarn. The technology not only improves the quality of existing dyeing or processing but also enables dark nylon dyeing and transfer printing.

In the industry where the supply of eco-friendly raw materials such as organic natural fibres or recycled synthetic fibres are already in short supply due to the recent trend where global companies declare more eco-friendly management, the new DOPHO-PLUS offers the brands and companies an opportunity to expand the use of eco-friendly fabrics. The FS Innovation has recently acquired GOTS (Global Organic Textile Standard) and GRS (Global Recycled Standard) certification.

FS Innovation has collaborated with major domestic and foreign companies through SUPPORTEX, a high-performance eco-friendly fabric brand and IASO FIL, an eco-friendly female athleisure brand by producing their products using this technology.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide