ExxonMobil opens advanced recycling plants in North America

YarnsandFibers News Bureau 2022-12-21 10:55:43 – USAExxonMobil has announced that one of North America's biggest advanced recycling facilities has officially started.

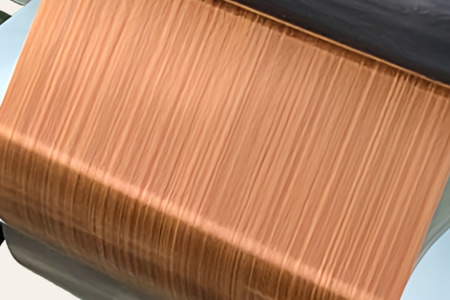

It is situated at the company's integrated manufacturing complex in Baytown, Texas, and employs specialized equipment to disassemble challenging polymers for recycling and turn them into raw materials for new goods. It can process more than 80 million pounds of plastic waste annually, helping to divert waste that would otherwise go to landfills.

Karen McKee, president of ExxonMobil Product Solutions, said that they've demonstrated their patented advanced recycling technology in Baytown, and now they're leveraging their scale and integration to enhance production of certified circular plastics to meet growing demand. There is a large market for recycled plastics, and by dissolving plastics that cannot be recycled mechanically, advanced recycling can play a significant role. In order to increase recycling rates and assist their clients all around the world in achieving their sustainability goals, they are working with the government, business, and communities to expand the collection and sorting of plastic trash.

Nearly 15 million pounds of plastic garbage have been recycled by ExxonMobil since the trial program at Baytown began last year. The patented Exxtend technology permits the breakdown of plastic trash that was previously intended for landfills, including bubble wrap, motor oil bottles, and synthetic football fields.

The corporation invested in a first-of-its-kind plastic waste processing facility in Houston to help supply the Baytown operation and assisted in the formation of Cyclyx International, a joint venture established to collect and sort massive volumes of plastic garbage.

ExxonMobil is a founding member of the Houston Recycling Collaboration, which unites business and government to enhance the infrastructure for mechanical and advanced recycling technologies and expedite advanced recycling.

By the end of 2026, ExxonMobil will be able to process up to 1 billion pounds of plastic trash yearly thanks to the construction of cutting-edge recycling facilities at several of its other industrial locations across the globe. Facilities in Baton Rouge, Louisiana, Beaumont, Texas, and Joliet, Illinois are being evaluated by the corporation, along with locations in Belgium, the Netherlands, Singapore, and Canada.

The business is also working with other parties to evaluate the likelihood of widespread adoption of cutting-edge recycling technologies as well as chances to promote advancements in plastic trash collecting and sorting in Malaysia and Indonesia. It has commercial agreements with companies including Amcor, Ahold Delhaize, Berry Global, and Sealed Air to sell certified circular plastics to clients all over the world for use in food-safe plastic packaging.

A circular economy may be accelerated and the problem of plastic waste can be solved with the help of advanced recycling, a tried-and-true technology. More plastic materials may be gathered, sorted, and recycled with the help of efficient government regulations designed to modernize the recycling system and enhance garbage collection. This is especially true of plastics that are now difficult to recycle.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide