Colorifix

Biotechnology company, Colorifix, has announced the completion of an 18 million pound Series B capital round headed by H&M Co:lab, the H&M Group‘s investment arm.

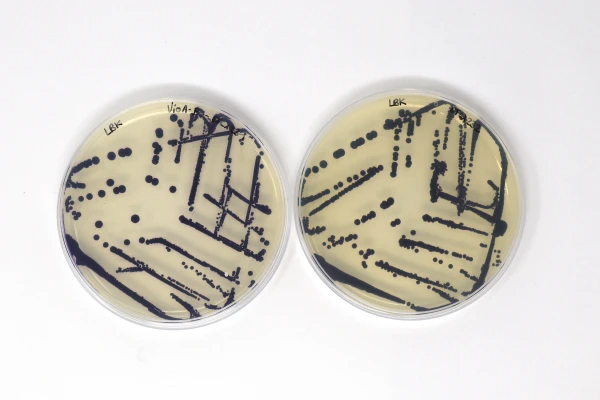

After its first client implementation with the Valérius Group in Portugal, the biotech business, which claims to be the first to pioneer a totally biological dyeing process, is trying to scale up to an industrial scale.

The eco-textile dyeing technique, which has already been introduced with H&M and Pangaia, aids in the sustainable transformation of the industry.

Colorifix’s chief operating officer, Chris Hunter, said that they’re happy that H&M Co:Lab has led this round, following smaller investments in our Seed and Series A. They have been tremendously helpful from the beginning and have demonstrated that they are the perfect partners to assist them to achieve on their expansion goal. They’re also grateful to have such a strong overall collection of strategic and theme investors that provide deep subject experience and strong international networks to their core emphasis areas and operating nations.

The funds will be used to triple Colorifix’s personnel as the company prepares to expand into Europe and Asia, introducing its technology into brand supply chains.

The majority of the company’s employees are now situated in Norwich, UK, where the company’s labs and offices are located, as well as a demonstration site in Cambridge. It also has a presence in London through The Mills Fabrica, a commercial partner, and is developing a subsidiary in Portugal, where it hopes to create an office.

Pascal Brun, H&M’s head of sustainability and Colorifix board director, said that they’re happy to continue to strengthen their collaboration with Colorifix and its excellent staff.

He added that supporting them during their exciting next phase of growth in scaling their unique game-changing technology speaks directly to H&M Group’s sustainability work, but it also has the potential to positively affect the entire industry.

Circulose has entered a strategic partnership with Tangshan Sanyou Chemical Fiber, marking a major step toward the commercialization and scaling…

LebaTex has launched a new faux leather collection featuring over 100 unique colors and textures, including polyurethane, vinyl, and silicone…

Gabriela Hearst has introduced eco-friendly sneaker line, named "Ohio," made from 30% recycled materials, reflecting the brand’s commitment to sustainability.

Oysho, the sportswear and leisurewear brand, has collaborated with Fulgar to introduce a new eco-friendly activewear collection made with Q-Cycle…

Autoneum has developed E-Fiber flame shields for electric vehicles, which stand out for their high-temperature resistance, lightweight structure and durability.

McLaren has introduced a world-first innovation in supercar engineering, Automated Rapid Tape (ART) carbon fibre redefining performance while reducing waste.