Circ launches Fiber Club to accelerate adoption of recycled textiles

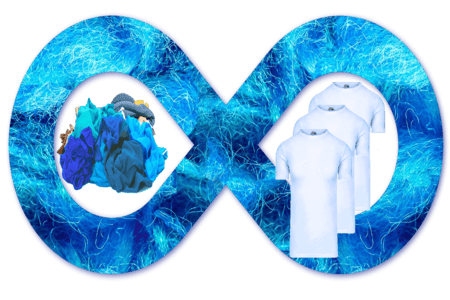

YarnsandFibers News Bureau 2025-01-29 16:21:15 – USACirc, a U.S.-based textile-to-textile recycling innovator, has unveiled Fiber Club, a pioneering initiative in collaboration with Fashion for Good and Canopy. Designed to streamline the adoption of recycled materials, Fiber Club offers brands a structured, four-phase process covering material sampling, pilot collections, and long-term off-take commitments.

The first fiber featured in Fiber Club is Circ’s staple lyocell fiber, with plans to expand to more recycled materials. Introducing new fibers into supply chains is often costly and complex, requiring high minimum order volumes. Fiber Club solves this by aggregating brand orders, simplifying supplier engagement, and reducing costs, making large-scale adoption more feasible.

Partnering with leading supply chain players Birla Cellulose, Arvind, and Foshan Chicley, along with brands like Bestseller, Eileen Fisher, Everlane, and Zalando, Fiber Club aims to scale sustainable textile solutions. Birla Cellulose will produce lyocell fiber from Circ’s recycled polycotton pulp, while Arvind and Foshan Chicley will develop textile fabrics for pilot production. Brands will then work with garment manufacturers to bring these materials to market.

“Fiber Club represents the future of textile recycling and circularity,” said Peter Majeranowski, CEO of Circ. “By collaborating with brands and streamlining supply chain integration, we’re making it easier than ever to adopt recycled and Next Gen materials at scale—starting with our Circ Lyocell.”

Unlike one-off pilots, Fiber Club is designed for long-term impact, creating a blueprint for future Next Gen material adoption. With Circ’s staple lyocell fiber as the starting point, the initiative sets a new standard for integrating circular materials into global supply chains, paving the way for a more sustainable fashion future.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide