Bolt Threads partners with Ginkgo Bioworks

YarnsandFibers News Bureau 2022-10-21 09:37:28 – USAGinkgo Bioworks, the leading horizontal platform for cell programming, and Bolt Threads, a biotechnology company developing the next generation of advanced materials, announced a multi-project collaboration to improve the performance and production efficiency of Bolt's current portfolio and to expand it by creating new proteins for biomaterials.

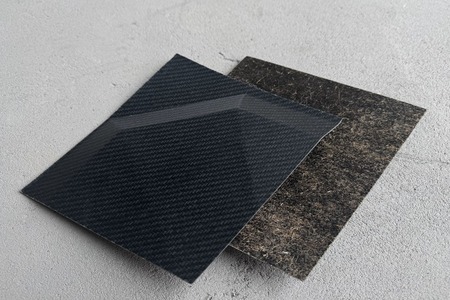

The initial initiative in this partnership is to increase the effectiveness of the manufacture of Bolt's Mylo™ material, a substitute for leather created from mycelium, the underground root-like system of fungi.

By working together, Ginkgo hopes to accelerate Bolt's mycelium's growth rate and reduce the overall cost of Mylo production. The firm's ongoing efforts to improve the efficiency, cost-effectiveness and sustainability of the b-silk™ protein manufacturing process at Bolt Threads are expanded through this collaboration.

Jason Kelly, CEO and co-founder, Ginkgo Bioworks, said that over the past few years, the top fashion companies in the world, as well as the textile industry as a whole, have come to understand the necessity of creating more environmentally friendly and sustainable fabrics. Mylo is a symbol of the future, and Bolt Threads is at the vanguard of this change. They’re thrilled to use their Foundry and Codebase to reduce the cost of manufacturing Mylo and make the product more available in a range of sectors where cutting-edge and intriguing alternative materials can be employed.

David Breslauer, co-founder and chief technology officer at Bolt Threads, said that Ginkgo's experience in engineering biology had helped them to expedite their work changing the clean beauty and personal care industries using b-silk protein. They are excited to work together once more to maximize the manufacturing of their mycelium technology, which will allow companies and customers alike to have easier access to Mylo.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide