Aracne

Eurecat, a technology center, and Canmartex, a textile business, have joined forces to create a new venture called Aracne. Aracne is focused on providing predictive quality control systems for the knitwear manufacturing process. Their plan is to launch their first product in the second half of 2023, with a sales target of €6 million by 2025.

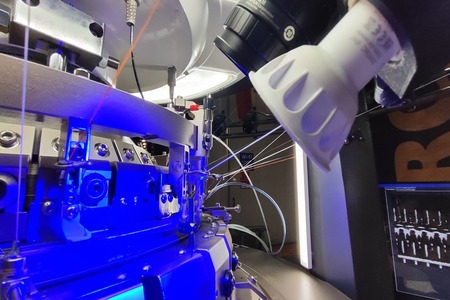

The Aracne system is designed to predict faults in the production process of knitwear, particularly in large-diameter circular knitting machines. These faults are often caused by issues like broken or worn machine parts. Aracne’s innovative technology, which combines photonic and Internet of Things systems with artificial intelligence algorithms, can anticipate potential manufacturing defects before the fabric is even made. This predictive approach significantly reduces production defects by more than 50%.

Apart from detecting faults in machine parts, Aracne also keeps a close eye on the fabric as it’s being manufactured. It can spot defects that may arise due to various reasons, such as problems with the yarn, mechanical issues, or holes in the fabric. This comprehensive monitoring ensures a higher level of product quality.

The key advantage of Aracne’s technology is its predictive nature, which can anticipate defects before they occur. This means that production managers can be alerted in advance, allowing them to assess the situation and take preventive measures. The ability to foresee and address potential defects is a game-changer in the industry.

This innovation, developed in collaboration with Canmartex, not only enhances product quality but also contributes to sustainability. It helps reduce production costs, boost efficiency, and supports the circular economy. It is a win-win for both knitwear weavers and large-diameter circular knitting machine manufacturers.

Aracne’s technology, which is built upon several patented solutions, is adaptable. Manufacturers can customize the system to suit their specific knitting machines. This flexibility makes it a valuable asset for businesses in the textile industry.

Milliken & Company has offered firefighter turnout gear with three layers, the outer shell, thermal liner, and moisture barrier, made…

Footwear brand Kanso is introducing the Dragonfly, a high-performance shoe designed specifically for indoor sports like handball, volleyball, and badminton.

Polartec is introducing an upgraded Power Shield collection with waterproof shell fabrics, made from recycled and plant-based nylons.

Coolia Activewear has introduced a groundbreaking fabric technology designed to transform the activewear market prioritizing performance and innovation.

Alsico Group, a leader in protective workwear, has announced a strategic partnership with Sixone, marking a major step toward sustainability…

At CHINAPLAS 2025, BASF will highlight its leadership in polyurethane (PU) innovation with groundbreaking advancements in recycling technology.