Uplift360 launches advanced fibers recycling process

YarnsandFibers News Bureau 2025-03-10 16:17:03 – FranceAt JEC World 2025 in Paris, Uplift360 showcased its proprietary chemical process that dissolves and re-spins para-aramid fibers, such as Kevlar and Twaron, into high-performance regenerated fibers. Uplift360 is working to ensure these valuable materials are recycled instead of discarded given they are highly expensive.

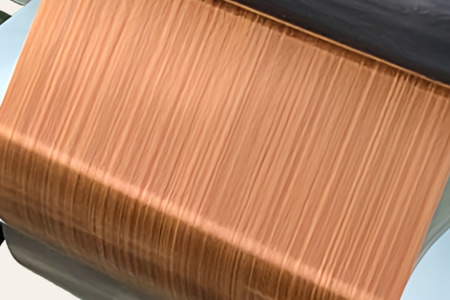

Uplift360’s technology employs a unique, non-sulphuric acid solvent system that is commercially available and recyclable. Using a dry-jet wet spinning process, the company converts waste aramids into liquid form before re-spinning them into continuous high-performance fibres.

This process not only recovers significant economic value but also establishes a fully circular fibre market, reducing reliance on virgin aramid production. Recent scale-up trials with key industry partners have successfully produced continuous fibers several hundred meters long. Additionally, Uplift360 has been selected to collaborate on European defence projects in 2025.

“Our breakthrough technology uses a unique solvent that is both commercially recyclable and highly effective,” said Jamie Meighan, co-founder of Uplift360. “This not only strengthens supply chain security but also significantly reduces the environmental impact of high-value material waste.”

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide