Lenzing introduces fossil-free process for stretch fabrics

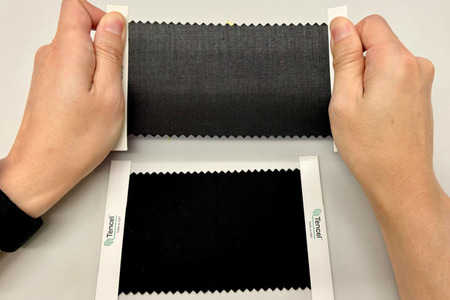

YarnsandFibers News Bureau 2024-01-18 16:18:27 – AustriaLenzing is tackling the fashion industry's dependency on fossil-fuel-based synthetics with a groundbreaking process. The Tencel lyocell manufacturer has unveiled a method that allows the wood-based fiber to produce fabrics with stretch and recovery properties, offering an eco-friendly alternative.

Rex Mok, Lenzing’s VP of Fiber Technical Marketing and Development, stated, "Our technical innovation unlocks the inherent potential of Tencel lyocell fibers for producing stretch fabrics that move in harmony with the body. This enhances comfort with easy-to-care properties, making it ideal for lightweight apparel."

Fossil-fuel-based synthetic fibers, known for their slow decomposition and contribution to greenhouse gas emissions, pose environmental challenges. Lenzing's innovative process offers a sustainable solution to create stretch fabrics, aligning with the industry's shift towards eco-friendly alternatives.

Lenzing is collaborating with mill partners to develop stretch fabrics meeting international standards for stretch and recovery properties. The new process, designed for shirting fabrics with a fabric weight below 200 gsm and a finer yarn count, holds promise for sectors like sportswear, athleisure garments, loungewear, and home textiles.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide