Arvind installs first Monforts Eco Line denim finishing range in India

YarnsandFibers News Bureau 2017-01-11 11:00:00 – AhmedabadArvind Ltd., India'' largest producer of denim, installed the first Monforts Eco Line denim finishing range in India at its Ahmedbad mill for faster production, major savings in energy, and greater flexibility in design and innovation for its customers.

The Eco Line can handle fabric widths of 1800 millimeters and operate at high speeds of up to 80 meters/minute, is operating alongside four Montex foam finishing stenters, which are also able to handle this same width of material.

Monforts Area Sales Director for Southeast Asia, Hans Gerhard Wroblowski, said that Arvind’s early investment in this new technology gives the company at least a year lead ahead of the competition from other Indian mills.

Aamir Akhtar, chief executive officer of Arvind Lifestyle Fabrics’ Denim division, said that in India the denim industry is growing at a compound annual growth rate of 13 to 15 percent. Arvind is rated in the top three denim producers in the world, and sees further export potential.

Arvind’s own export-domestic output is around 50:50, but some of the domestic production is worked up into garments and exported, so distorting the figure: taking that factor into account, Akhtar believes that the export proportion is closer to 60 percent.

Akhtar confirmed that Arvind stays ahead of its competition through a policy of design and innovation. They also have their own major R&D facility. Having been a Monforts user from the earliest days, they had no hesitation in investing in the new Eco Line.

Not only does this make them even more responsive to customer needs and demands, and more creative in their design and production, there is also the very great energy saving advantage and tight control over emissions.

The Eco Line was manufactured in Monforts production facility ‘MONTEX’ in Austria and installed by Monforts’ representive in India, ATE Enterprises Private Ltd.

C V Babu, ATE’s General Manager for Sales at the company’s Ahmedabad office, said that the Eco Line system reduces energy losses and energy use, increases thermal transfer and keeps the drying energy on the textile material longer, so that it can be used very efficiently.

As a result, energy savings of up to 50 % can be achieved. Exhaust air energy can also be reduced to a minimum, which has a positive effect on the emission load into the atmosphere.

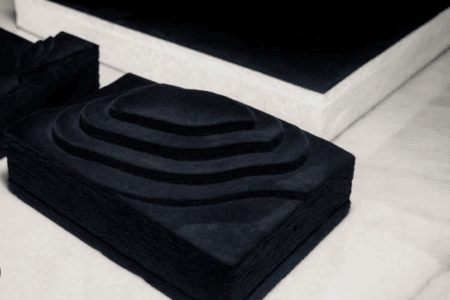

Arvind’s current annual denim capacity is 110 million meters, with prominent products including ring denim, indigo voiles, organic denim, bi-stretch denim and fair trade certified denim.

This is apart from regular light, medium and heavyweight denims. They come in various shades of indigo, sulphur, yarn-dyes, in 100 percent cotton and various blends.

Denim is a great lifestyle product and it is also tremendously versatile.They are very, very upbeat about their global future.

Arvind founded in 1931 as a maker of traditional Indian clothing, but in 1984 modernized and brought denim into the domestic market, thus starting the jeans revolution in India.

Today it retails its own brands like Flying Machine, Newport and Excalibur, and licensed international brands like Arrow, Lee, Wrangler and Tommy Hilfiger, through its nationwide retail network.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide