The conclusion of Phase 1 of the DuPont, Fibrtec project validates the advancements that can be made in the carbon fiber composites production field

YarnsandFibers News Bureau 2018-08-10 11:07:00 – KnoxvilleThis project offers a new CFRP manufacturing process when compared to the two other typically deployed processes which have significant drawbacks that limit their mainstream, high-volume use in the automotive and aerospace industries. One mainstream current technique weaves dry carbon fiber tows into a fabric, layers the fabrics with thermoplastic resin films, and later heats and compresses them into a well-consolidated composite. While this method is ultimately effective in creating a carbon fiber fabric, the process has several drawbacks.

One downside is that the carbon fibers often break during the weaving process, releasing short, conductive carbon fiber strands into the local environment. Therefore, the surrounding looms and equipment must be electrically isolated. Another drawback is the relatively slow speed which is associated with this traditional process. Creating carbon fiber composites through this weaving method is roughly one-third the speed of that required to make glass fiber-based fabrics.

A second typical technique is the impregnation and flattening of carbon fiber tows with a thermoplastic resin to make a low-void, fully consolidated composite tape. These tapes are then woven or placed and tacked to form a fabric, which is then rapidly consolidated into the final composite part.

A major issue with this process is the handling of the UD tapes because they are stiff and brittle, and therefore can fracture when bent to tight radii at room temperature. This stiffness property makes fabric formation from tapes a slow and expensive process.

The conclusion of Phase 1 of the DuPont, Fibrtec project validates the advancements that can be made in the carbon fiber composites production field, and reveals new opportunities for the application of carbon fiber composites into the automotive and aerospace industries as carbon fiber composites become easier and safer to produce making them more affordable, and viable for mass production.

Robert Davies, Fibrtec’s Chief Executive Officer said that, “Fibrtec’s contribution of its globally differentiated thermoplastic composites to this IACMI Phase I joint project with DuPont and Purdue University has helped to deliver breakthrough results on the IACMI goals. Tapping into the innovation of small and medium sized organizations (SMEs), like Fibrtec, and the forging of public/private partnerships through IACMI’s framework is accelerating the insertion of structural composites in the automotive industry. It is a fantastic opportunity for companies like Fibrtec to have access to world-class resources not normally available to them and we look forward to continuing Phase II.â€

The objective of this program is to reduce the cost of manufacture of carbon fiber reinforced polymer composites by using a near net shape process such as automated fiber placement (AFP) on a relatively inexpensive carbon fiber/polymer tow-preg. The coated tows are easily manipulated, and the resulting pseudo-fabrics are readily draped and conform effortlessly during molding without shear locking. Project partners projected that with this strategy, the process would be able to use the expensive carbon fiber only where it is required, reducing the carbon fiber waste by up to 30 percent, and creating fiber preforms that predictably deform during compression prior to molding. The Phase I project conclusion resulted in better than expected outcomes with embodied energy being reduced by more than 40 percent using this processing scheme.

IACMI Chief Executive Office, John A. Hopkins said that, “We are pleased by the outcomes of Phase I and look forward to continued development of these advanced carbon fiber composite materials,†Also, “Through the second phase of this project we will more fully characterize these novel carbon fiber thermoplastic prepreg forms and validate their use in molding processes suitable for high-rate, cost-sensitive applications. This will showcase their suitability for large-scale deployment, especially in the automotive industry, which is an important part of our long-term goals to reduce energy use.â€

Jan Sawgle, Program Manager DuPont Transportation and Advanced Polymers said that, This project addresses some of the most challenging aspects of composites manufacturing and commercial adoption in high volume market applications. Phase I completion signals a step forward in demonstrating a significant impact in the ability to make lower cost parts with the design freedom to meet performance requirements of challenging applications. This was one of the earliest projects launched by IACMI and it serves as a great example of collaboration and partnering to accelerate innovation. We look forward to continuing our progress in Phase II."

Michael Bogdanor, director of the Composites Design Studio in the Purdue Composites Manufacturing and Simulation Center said that, “The synergy between Purdue, Fibrtec, and DuPont on this project demonstrates the power of public-private partnerships in fostering innovation and delivering novel solutions to real-world problems. In this project, we focused on manufacturing informed performance, which is of critical importance in the design of composite components and structures,†Also, “Phase I of this project was instructive in developing new simulation tools to be able to predict the behavior of the RFF and FibrFlex technologies. This resulted in new methods to predict the behavior of the material system in manufacturing as well as the ultimate performance of parts.â€

The Institute for Advanced Composites Manufacturing Innovation (IACMI), a 160+ member, University of Tennessee, Knoxville and U.S. Department of Energy driven consortium committed to increasing domestic production capacity and manufacturing jobs across the U.S. composites industry, announces the Phase 1 completion of a project led by DuPont, with project partnership from Fibrtec and Purdue University. The conclusion of Phase I validates the creation of a new carbon fiber composite manufacturing process that exhibits improved fabric formability characteristics compared to traditional woven materials.

The implications of the Phase I results are driving Phase II of the project, and can ultimately lead to a decrease in cost for carbon fiber composite structures, making them more amenable for adoption in the automotive and other high volume industries, reduce embodied energy, and can directly lead to a creation of jobs in the industry.

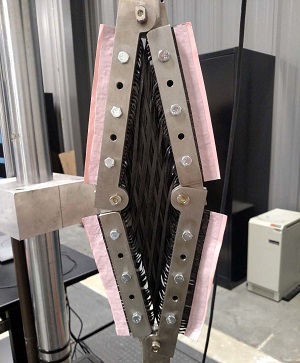

This new material created through this IACMI project combines Fibrtec’s flexible coated tow, FibrFlex™, with DuPont’s Rapid Fabric Formation (RFF) technology, and a proprietary DuPont polyamide resin, all supported by Purdue University’s extensive modeling and characterization capabilities. The coated tow material is a partially impregnated carbon fiber/polyamide composite tow where the carbon fiber is not fully wetted with the polyamide, yielding a more flexible tow material than one that is fully impregnated.

The RFF process is an ultra-fast way of manufacturing fabrics with tows in varying orientations without the need to lift the tow during processing. Experiments, modeling, and simulations, all have shown that this process/materials combination is a potential method for producing lower cost continuous fiber reinforced polymer (CFRP) thermoplastic materials that conform well during molding with outstanding physical properties.

Market Intelligence

Ask for free sample Report

experience

Customer Base

dedicated team

Countries Served Worldwide